Glassblowing...a demonstration

July 28, 2009

I’d read in the paper about the

(here it is)

having a

glass-blowing demo every third Friday of the month

and decided to go…and it was extremely interesting!

Here’s an account and photos on

(If you scroll down, you will come to where the pics from the July demo are posted…and in pics 13 and 14, if you look behind the glassblower, you can see

But of course I took my own pics and videos, and my videos explain the process better (because they won’t show it all on their website, would they?)

The glass is "gathered" from the oven, in several layers; the oven is around 2200 deg C! (The annealing oven is cooler..but badly made glass can crack or shatter in the annealing oven, too.)

v

The glass is "gathered" from the oven, in several layers; the oven is around 2200 deg C! (The annealing oven is cooler..but badly made glass can crack or shatter in the annealing oven, too.)

v The glass is shaped in these receptacles of water:

The glass is shaped in these receptacles of water:

One person blows, while the other shapes the glass:

One person blows, while the other shapes the glass:

Sometimes impurities are taken out:

Sometimes impurities are taken out:

Slowly the vase begins to take shape:

Slowly the vase begins to take shape:

A blowtorch is used to shine up the outside:

A blowtorch is used to shine up the outside:

The glass is also shaped with wet newspaper:

The glass is also shaped with wet newspaper:

Cuts are being given at the neck of the glass item:

Cuts are being given at the neck of the glass item:

Sometimes the shape of the bottles means swinging around to shape the gather:

Sometimes the shape of the bottles means swinging around to shape the gather:

Here are some of the articles made:

Here are some of the articles made:

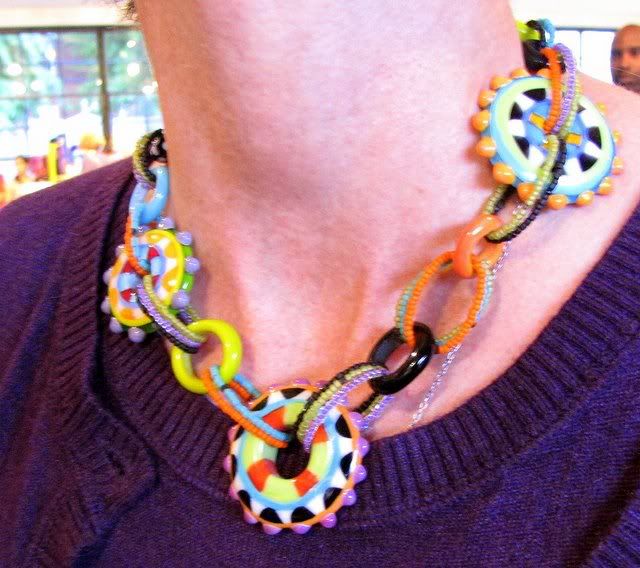

This necklace, said the wearer, was made earlier in this studio!

This necklace, said the wearer, was made earlier in this studio!

They even have their message on their van:

They even have their message on their van:

The finishing touch was when A told me to go and look at the toilets, I was delighted to find beautiful basins there, too…this was the most artistic restroom I have visited in the US!